Prevent Tragedies - Accident Analysis Models and ProSREM

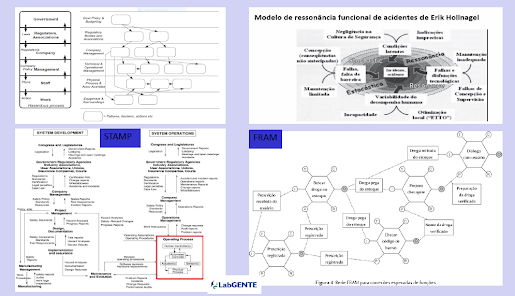

Figure - Accident analysis models

Analysis

models and methods

Accident analysis models and methods

provide safety professionals with a means of understanding why accidents occur.

Choosing an analysis technique is, however, not a simple process. A wide range

of methods are available; each offering various theoretical and practical

benefits and drawbacks. Furthermore, individuals engaged in accident

investigation are subjected to various factors, e.g. budgetary and time

constraints, which can influence their selection and usage of an analysis tool.

Ref: Accident Analysis

Models and Methods: Guidance for Safety

Professionals

Peter Underwood and Dr. Patrick Waterson

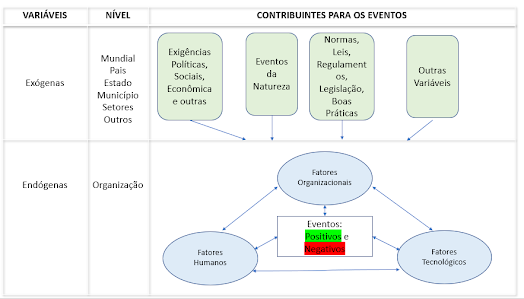

A key driver for the continued rise in

analysis model and method numbers is the ever-increasing complexity of

socio-technical systems (which are comprised of interacting human,

technological and environmental components) and the resulting change in

accident causation mechanisms. As researchers have sought to account for these

changes, the ensuing development of analysis techniques can be described as

having gone through three major phases, i.e. sequential, epidemiological and

systemic. This categorization relates to the different underlying assumptions

of accident causation (Hollnagel and Goteman, 2004). This distinction is not

obligatory and other classification systems based on differing accident

characteristics exist (e.g. Kjellén, 2000) (Katsakiori et al., 2009). However,

it helps explain the desire of researchers to introduce systems theory concepts

into accident analysis, as detailed in the following sections.

Sequential techniques

The sequential class of models and methods describes

accidents as the result of time-ordered sequences of discrete events. They

assume that an undesirable event, i.e. a ‘root cause’, initiates a sequence of

events that lead to an accident and that the cause-effect relation between

consecutive events is linear and deterministic. This implies that the accident

is the result of this root cause which, if identified and removed, will prevent

a recurrence of the accident. Examples include the Domino model (Heinrich,

1931), Fault Tree Analysis (Watson, 1961 cited in Ericson, 1999) and the Five

Whys method (Ohno, 1988).

These methods work well for losses caused

by physical component failures or the actions of humans in relatively simple

systems and generally offer a good description of the events leading up to an

accident (Leveson, 2004). However, the cause-effect relationship between the

management, organisational and human elements in a system is poorly defined by

these techniques and they are unable to depict how these causal factors

triggered the accident (Rathnayaka et al., 2011). From the end of the 1970’s it

became apparent that the sequential tools were unable to adequately explain a

number of major industrial accidents, e.g. Three Mile Island, Chernobyl and

Bhopal.

Consideration for the role that

organisational influences play in accidents was required and resulted in the

creation of the epidemiological class of analysis tools.

Epidemiological techniques

Epidemiological models and methods view

accidents as a combination of ‘latent’ and ‘active’ failures within a system,

analogous to the spreading of a disease (Qureshi, 2007). Latent conditions,

e.g. management practices or organisational culture, are likened to resident

pathogens and can lie dormant within a system for a long time (Reason et al.,

2006). Such organizational factors can

create conditions at a local level, i.e. where operational tasks are conducted,

which negatively impact on an individual’s performance (e.g. fatigue or high

workload). The scene is then set for ‘unsafe acts’, such as errors and

violations, to occur. Therefore, the adverse consequences of latent failures

only become evident when they combine with unsafe acts, i.e. active failures,

to breach the defences of a system. The most well-known epidemiological

technique is the Swiss Cheese model (Reason, 1990, 1997), which has formed the

conceptual basis for various analysis methods, e.g. the Human Factors Analysis

& Classification System (HFACS) (Wiegmann and Shappell, 2003) and Tripod

Beta.

The epidemiological class of techniques

better represent the influence of organisational factors on accident causation,

when compared with the sequential tools. Given that they require an individual

to look beyond the proximal causes of an accident and examine the impact of a

system’s latent conditions, a more comprehensive understanding of an accident

can be achieved. However, many are still based on the cause-effect principles

of the sequential models, as they describe a linear direction of accident

causation (Hollnagel, 2004). From the late 1990’s, a number of researchers e.g.

(Rasmussen, 1997; Leveson, 2001; Svedung

and Rasmussen, 2002) argued that these epidemiological techniques were no

longer able to account for the increasingly complex nature of socio-technical

system accidents. The application of systems theory was subsequently proposed

as a solution to this issue.

Systemic techniques

Systems theory is designed to understand

the structure and behaviour of any type of system. Rather than treating

accidents as a sequence of cause-effect events, it describes losses as the

unexpected behaviour of a system resulting from uncontrolled relationships

between its constituent parts. In other words, accidents are not created by a

combination of latent and active failures; they are the result of humans and

technology operating in ways that seem rational at a local level but

unknowingly create unsafe conditions within the system that remain uncorrected.

From this perspective, simply removing a ‘root cause’ from a system will not

prevent the accident from recurring. A holistic approach is required whereby

safety deficiencies throughout the entire system must be identified and

addressed. A range of systemic tools exist which enable the application of the

systems approach, e.g. the Systems Theoretic Analysis Model and Processes model

(STAMP) (Leveson, 2004, 2011), the Functional Resonance Analysis Method (FRAM)

(Hollnagel, 2004, 2012) and the Accimap (Rasmussen, 1997).

Whilst these systemic techniques appear to

provide a deeper understanding of accident causation, various studies suggest

they are more resource intensive and require considerable amounts of domain and

theoretical knowledge to apply (e.g. Ferjencik, 2011; Johansson and Lindgren,

2008).

Furthermore, the latest version of the

Swiss Cheese model (see Reason, 1997) acknowledges that active failures are not

always required for an accident to happen; long-standing latent conditions are

sometimes all that is required, as was the case in the Kings Cross, Piper Alpha

and the space shuttles Challenger and Columbia accidents (see Reason et al.,

2006). It also acknowledges that latent conditions can be better described as organizational

factors, rather than management failures. This represents top-level managerial

decisions as ‘normal behaviour’ influenced by the local conditions, resource

constraints and objectives of an organisation.

The distinction between the epidemiological

and systemic perspective of accidents, therefore, seems to be a subtle one.

However, a number of studies have compared systemic methods with established

Swiss Cheese based methods, such as HFACS (Salmon et al. 2012) and the Systemic

Occurrence Analysis Methodology (e.g. Arnold, 2009) and commented that the

systemic techniques do provide a deeper understanding of how the behaviour of

the entire system can contribute to an accident.

Whilst the ‘systems approach’ is arguably

the dominant concept within accident analysis research, systemic models and

methods are yet to gain widespread acceptance within the practitioner community

(Underwood and Waterson, 2013).

Comentários

Postar um comentário