Risk Management Training, and The Proactive Safety Method, Risks and Emergencies. Participate, specialize and support the dissemination of this initiative. This article initially presents the international article approved in JRACR journal, English version: The Sociotechnical Construction of Risks, and Principles of the Proactive Approach to Safety, and after the Risk Management Training, and The Proactive Safety Method, Risks and Emergencies

"Safety" is sociotechnically constructed.

Risk Management Training, and The Proactive

Safety Method, Risks and Emergencies

Participate, specialize and support the

dissemination of this initiative.

This article initially presents the international

article approved in JRACR journal, English version: The Sociotechnical

Construction of Risks, and Principles of the Proactive Approach to Safety, and

after the Risk Management Training, and The Proactive Safety Method, Risks and

Emergencies

Below is the article approved in the international journal JRACR: The sociotechnical construction of risks and the principles of Proactive Safety.

Available in:

Article

The Sociotechnical

Construction of Risks, and Principles of the Proactive Approach to Safety

Washington Barbosa1,2*, Luiz Ricardo

Moreira 2, Gilson Brito3, Assed N. Haddad4, and

Mario Cesar Vidal 2

1 Oswaldo Cruz Foundation,

Rio de Janeiro (21040360),

Rio de Janeiro, Brasil

2 Production

Engineering Program, Federal University of Rio de Janeiro, Rio de Janeiro (21941914), Rio de

Janeiro, Brasil

3 Production

Engineering Program, Federal University Fluminense, Niterói (24210240),

Rio de Janeiro, Brasil

4 Environmental

Engineering Program, Federal University of Rio de Janeiro, Rio de Janeiro (21941909), Rio de

Janeiro, Brasil

* Correspondence

autor: washington.fiocruz@gmail.com

Received: December 17, 2022; Accepted: February 17, 2023; Published: March 31, 2023

DOI: https://doi.org/10.54560/jracr.v13i1.353

Abstract:

This proposal presents the

Sociotechnical Construction of Risks, Ergonomics, and the two principles of the

Proactive Approach to Safety, Risks, and Emergencies, the Structured Sociotechnical Approach and Dynamics

of Proactive Safety intending to complement traditional risk

assessments, and prevent and Mitigating Major and Fatal Negative Events, the in

organizations such as cases of the explosion of the space shuttle Challenger,

the nuclear accident in Fukushima, the Texas City Refinery and the explosion in

the Port of Beirut, among others. To propose these two principles, case studies

were developed at Fiocruz, and in organizations, sectors, and activities, a

bibliographic review on theses, dissertations, reports from regulatory bodies,

books, scientific articles, and media articles, on major and fatal negative

events, and ergonomics, socio-technical approach, and resilience engineering. A

tragedy prevention course was created, with four free online consultation

modules, based on cases of major negative events. These principles redirect the

focus from human error to Focus on the Structured Sociotechnical System and

Focus on the Dynamics of Proactive Safety. It is proposed that these two

principles can provide us with bases for analysis, to prevent and minimize

Major and Fatal Negative Events, and are a complement to traditional risk

assessments.

Keywords: Ergonomics; Safety, Diagnosis; Method; Risk Management;

Proactive Safety from Risks and Emergencies.

The use of risk management, risk assessment, and

risk analysis emerged more or less independently in several areas: Nuclear

Industry, Insurance, Oil Industry, Safety at Work, Corporate Security,

Financial systems, Information Security, and Security of Products and

Processes.

The word risk is used in many areas and with

different meanings, such as in mathematics, economics, engineering, and the

field of public health.

Safety is a state of low probability of occurrence of

events that cause damage or loss.

The term safety culture was conceptualized for the first

time in the technical report on the accident at the Chernobyl nuclear power

plant in Ukraine, in the 1980s, as being:

“Set of characteristics and attitudes of organizations

and individuals, which guarantee that the safety of a nuclear plant, due to its

importance, will have the highest priority”

Accident is defined as: “an undesirable event that

results in death, health problems, injuries, damages and other losses”.

Near-miss is defined as: “an unforeseen event that had

the potential to cause accidents”. This definition is intended to include all

occurrences that do not result in death, ill health, injury, harm and other

benefits.

The term “incident” cited is defined as: “an unsafe

occurrence arising from or in the course of work, in which no personal injury

is generated”. This term was added to include all occurrences that generated

only material damage and near-accidents in the organizations' focus of action.

Despite

the efforts made by companies, organizations, private sectors, and the

government, a series of major and fatal negative events have happened, such as

the explosion of the space shuttle Challenger, the nuclear accident in

Fukushima, and the explosion in Port of Beirut, among others (Barbosa, 2022).

Turner

(1994) analyzed serious technical accidents over a long period and concluded

that approximately 20 to 30% of the causes of accidents were technical, with 70

to 80% involving social, administrative, or managerial factors.

A series

of studies on air and maritime accidents in Qureshi (2008) showed human and

organizational factors as the main contributors to accidents and incidents. An

analysis of major air and maritime accidents in North America during 1996-2006

concluded that the proportion of causal and contributing factors related to

organizational issues exceeds those due to human error. For example, the combined

causal and contributory factors of aviation accidents in the US showed: 48%

related to organizational factors, 37% to human factors, 12% to equipment, and

3% to other causes; and the analysis of maritime accidents classified causal

and contributory factors as 53% due to organizational factors, 24-29% as human

error, 10-19% for equipment failures and 2-4% as other causes.

Why do

negative events happen?

These

complex events require both a socio-technical approach and a working

conceptualization of these systems.

According

to Llory (2014), however diverse the causes of these accidents are, they all

have an organizational dimension, that is, their root causes must be sought to

verify what caused the accident. They also confirm that the non-occurrence of

serious accidents and good performances in everyday life can hide an important

issue, as a catastrophe may be about to happen.

In this

way, the objective of the research can be presented as follows:

Principles

can be developed, with analysis of these accidents and case studies, according

to Barbosa, 2022, in search of factors and variables, which present proposals

for the prevention and minimization of these accidents, which happen

repeatedly, and that can be transmitted to the organizations.

Initially,

a case study was developed, conducted by the author that originated a monograph

of the specialization course in Ergonomics: "Ergonomic Analysis of Risk

Management of Residues of Dangerous Products from Fiocruz" and an article

by the author on the "Contribution of Ergonomics to the Development of

Proactive Safety, Risks and Emergencies of Waste from Fiocruz Dangerous

Products”, presented in the panel of articles approved at the Abergo 2020

Congress. (Barbosa, 2020)

As a

continuation of this research, an in-depth literature review was carried out on

theses, dissertations, reports from regulatory bodies, books, scientific

articles, and media articles, on major and fatal negative events, ergonomics,

socio-technical approaches, and resilience engineering. The initial cases

presented in Barbosa, 2022 were selected, and the research continued in units,

sectors, and services at Fiocruz and in organizations. Regarding Fiocruz, as

the author is an employee of Fiocruz, he can carry out several visits to these

places, and talk to the Management, Department Heads, Researchers, Engineers,

Architects, and Technicians in the areas of research, infrastructure, and

management, about the other organizations, confidentiality was requested. This

work began in 2016, with the evaluation of the management of Fiocruz's

hazardous products, and has continued in the research laboratories and Fiocruz

units, in other teaching and research institutions, and in other organizations,

until the date of presentation of this work because one of the author's main

activities is the safety assessment of the facilities and services provided by

organizations.

A

tragedy prevention course was also created, with four free online consultation

modules, in a blog by the author, with a base of cases of major negative events

that are hosted in module three (Barbosa, 2022).

2. Literature Review

Traditionally,

in the analysis of negative and fatal events, the blame is directed towards

workers, who are the most fragile elements of the companies' chains of command,

and there is little analysis of the activities performed by workers, and their

consequences in procedures and adequate working conditions, supervision and

management of activities, investments in the maintenance of facilities,

analysis, and adaptation of projects, company policies, remuneration bonuses

for Directors and Managers, social and economic requirements, and analysis of

the legislation applied to the activity, among other issues. Safety management

researchers have focused on this topic in recent decades and have presented

their proposals for analyzing the factors that give rise to these negative

events.

2.1. Evolution of the periods of the analysis of negative and

fatal events

According

to Dechy (2011), we can present the evolution of these periods:

-

Technical period until the 1970s: the source of problems is seen as technology;

security was primarily based on technical reliability,

- Period

of “human error” in the 1980s: the source of the problem is seen as the person

in particular the operators after the Three Mile Island accident in 1979;

allowed improvements in the domains of the human-machine interface, design of

operational procedures, training, among other activities.

- Socio-technical

period in the nineties: After Bhopal (1984), Challenger and Chornobyl (1986)

the source of the problem is seen as the interaction between the social and the

technical subsystems; Furthermore, the concept of “Safety Culture” emerged

after the Chornobyl accident;

-

Interorganizational relationship period from the 2000s: the source of the

problem is dysfunctional relationships between organizations, in particular

with the controlling role of authorities, subcontractors, competitors, and

other departments within an organization

The

results of this evolution are cumulative, not exclusive, and none of these

dimensions should be neglected when analyzing an event, as they all provide

useful information for the world to understand the dynamics that gave rise to

the accident.

2.2. Theories and research related to the analysis of accidents

and management of organizations

We

highlight theories and research related to the analysis of accidents and

management of organizations, which have worked with the history of Safety and

also contribute to the work presented in this article.

According to Hollnagel (2006), we need to have the

etiology of accidents, a study of possible causes or origins of accidents, we

also need to have a safety etiology – more specifically what safety is and how

it can be in danger. This is essential for system safety work in general and

resilience engineering in particular. However, for reasons that are not

entirely clear, development is lacking. The different perceptions of the

accident phenomenon are what in current terminology are called accident models.

Accident models appear to have started with a relatively single factor from

simple models, and developed via simple and complex linear causality models to

present-day systemic or functional models.

Greenwood

and Woods, presented in 1919 the theory that proposed an individual propensity

of workers to accidents at work, in 1931, Heinrich proposed another theory in

which a sequence of factors can cause the accident, in a linear sequence of

falling domino pieces, aligned side by side, in which the fall of one piece

triggers the fall of the other pieces on the side, in a linear sequence of

events, called the Domino Theory. It is a linear cause-and-effect model. In

this theory, it was argued that it would be possible to avoid the accident,

even after the first domino piece had fallen if one of the stones in the

sequence was removed. Heinrich states that about 88% of accidents are due to

unsafe acts, 10% to dangerous conditions, and 2% to fortuitous situations, this

perspective remains one of the preponderant theories in the area of safety in

organizations.

Turner

(1978) analyzed 84 accidents and disasters in all sectors, presenting the idea

that social, technical, and administrative interactions systematically produced

disasters; and also developed the concept of accident incubation, with a

six-stage development sequence:

1.

Normal state, initially accepted beliefs about the world and dangers.

Precautionary norms in laws, codes of practice, or traditional customs.

2.

Incubation period, accumulation of a set of unnoticed events at odds with

accepted beliefs about hazards and norms for controlling them.

3.

Precipitating event, disaster begins, general perception changes, surprise, and

disturbances occur.

4.

Events escalate, consequences become apparent, and collapse occurs.

5.

Rescue and rescue.

6.

Complete cultural readjustment. Investigation. Beliefs and norms of precaution

are adjusted to suit the newly acquired understanding of the world (“this must

never happen again”).

Perrow

(1984) analyzed large-scale accidents, which are a problem for society.

According to Perrow, high-risk organizations with complex technological systems

have structural properties that make these large-scale accidents impossible to

predict and avoid. For this reason, in these complex systems, accidents are

considered “normal” events, and on this basis, he named the theory of normal

accidents, where he concludes that these accidents will repeat themselves, and

suggested that some of these systems should be eliminated, due to risks of the

occurrence of these accidents, the interaction of multiple failures stands out

in these normal accidents, whose operational sequence is not direct. The

difficulty in anticipating these situations. it is due to the infinite number

of possible interactions between failures in the various components of complex

systems.

Reason’s

(1997) model, known as “Swiss Cheese” or the theory of multiple causes, does

not defend a single cause as the trigger for a sequence of events that would

lead to the accident, but linear combinations of latent conditions and active

failures that constitute several chains. and, after overcoming safety barriers

by aligning their vulnerabilities, they culminate in an accident. In this

theory, the influence of the organization in the occurrence of accidents stands

out. Thus, investigations must look for latent conditions that may induce

situations conducive to active failures. Thus, the most effective prevention

should identify hazards or threats and manage the risks.

Rasmussen

(1997) developed the Accimap, which focuses on failure analysis at the

following six organizational levels: government policy and budget; regulatory

bodies and associations; company planning and budgeting; technical and

operational management; physical processes and activities; and equipment, it is

a proposal with a generic approach and does not use failure taxonomies at

different levels of analysis.

Leveson's

(2004) STAMP model is based on levels of control of the socio-technical system.

According to the theory behind STAMP, accidents occur due to the violation of

the conditions in which the system was designed, to support the identification

of violations, a taxonomy of control failures is proposed.

FRAM, Hollnagel, (2004, 2012), is a method

that aims to understand how systems work and how variability propagates between

their functions, to develop more resilient systems.

Using

this model can identify conditions that can lead to accidents in four steps:

•

Identify and characterize the essential functions of the system, for example,

based on the six connectors described;

•

Characterize the variability potential of these connectors;

• Define

functional resonance based on identified dependencies between functions;

•

Identify barriers to variability (reduction factors) and specify required

performance monitoring.

Below is

a Theoretical Framework of Contributions:

Table 1

– Accident Model Theoretical Framework. Self-elaboration.

|

Author |

Year |

Contribution

to Safety |

Spatial,

School, Georeferenced |

Major Contribution to

Proactive Safety |

|

Greenwood

e Woods |

1919 |

Theory about the existence

of individual workers' propensity, sought to explain the causality of

accidents at work. |

United

States |

Historical

View |

|

Heinrich |

1931 |

Theory in which the accident

originates in a linear sequence of events, which he called the Domino Theory. |

United

States |

Beginning of a more

technical analysis, and based on negative events. |

|

Turner |

1978 |

Accident incubation concept,

and a six-stage development sequence. |

England |

Dynamic risk management

concept, and based on a series of case studies of major negative events. |

|

Perrow |

1984 |

Normal Accident Theory. |

United

States |

Social Construction of Risk, and that accidents

are inevitable, as alignment of its causes is unique and

not repeatable. |

|

Reason |

1997 |

Swiss Cheese Model” or the

theory of multiple causes, does not defend a single cause as triggering a

sequence of events that would lead to the accident, but linear combinations

of latent conditions and active failures that constitute several chains and,

after overcoming safety barriers by the alignment of their vulnerabilities,

culminate in the accident. |

England |

Evolution of Domino Theory

and concepts of safety barriers. |

|

Rasmussen |

1997 |

Accimap model, which focuses

on failure analysis at the six organizational levels. |

Denmark |

The concept of performance

levels in risk management evolves to the proposal of exogenous and endogenous

variables. |

|

Leveson |

2004 |

The

STAMP theory is that accidents occur due to the violation of the conditions

in which the system was designed. |

United

States |

Evolution of the Accimap

Model. |

|

Hollnagel |

2004 |

FRAM is a method that aims

to understand how systems work and how variability propagates between their

functions, aiming to develop more resilient systems. |

Denmark |

The complexity of systems,

but it is important to seek the representation of complexity, so I present

the proposal of the 2 models and principles of Proactive Safety. |

2.3. Social

Construction of Risk

It must

be accepted that the risk is derived from the organization, through its

decision-making processes at the strategic, tactical, and operational levels,

that is, the risk is a technically constructed partner, according to Dechy

(2011), Figueiredo (2018), Filho (2021), Hollnagel (2019), Hopkins (2008), Le

Coze (2013), Levenson (2020), Llory (2014), Pidgeon (2000), Perrow (1999),

Rasmussen (2000), Reason (2016), Turner (1997), Vaughan (1996).

And to evaluate

it, adequate qualitative methods are needed for the socio-technical question.

It is

necessary to go beyond the analysis of human and technical factors, compliance

with legislation, and good practices to improve risk management.

These

questions are important and basic for understanding risk management and for

preventing Major and Fatal Negative Events.

3. Methodology

The principles of Proactive Safety, Risks, and

Emergencies are developed through two models.

3.1. Analysis of Modeling

Study on the elements of the

general organization of work in the organization, which were based on the study

of major and fatal negative events presented in Barbosa, 2020 and 2022, to know

and initiate an analysis, through modeling.

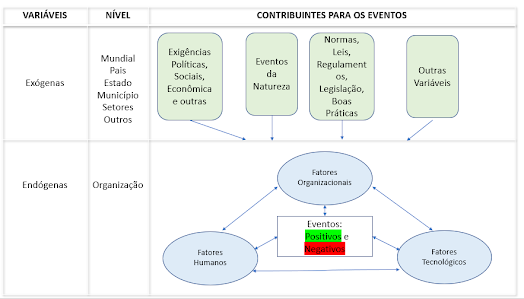

3.1.1. Structured Sociotechnical Approach

The socio-technical approach is divided into

organizational, human, and technological factors, which I define as endogenous

variables.

As a contribution to this proposal for a

sociotechnical approach, I present, based on the case studies research for this

work, major and fatal negative events, at the international, national, and

local levels (Barbosa, 2022) and the

Accimap Model Rasmussen (1997), a proposition of the

structured sociotechnical approach, where they are included in this analysis

are the contributors: social, economic and other requirements; norms and

legislation at the World, Country, State, Municipality and Sector levels, which

I define as exogenous variables. As a result of the interaction between

exogenous and endogenous variables, positive and negative events will occur,

which will be shown in Figure 1.

Figure 1. Structural Sociotechnical

Approach. Self-elaboration.

The Exogenous Variables are

the contributors to the event, external to the organization, a possible

classification of level can be at the World, Country, State, Municipality,

Sectors, and others, as examples, we can highlight international, national,

sectorial, state, municipal standards of security, the economic requirements of

recession and economic growth, events of nature, and other variables, which

were not verified in the case studies analyzed in Barbosa (2022), such as

terrorism, sabotage, theft, and vandalism, among others, present in other

unanalyzed negative events.

The Endogenous Variables are the Organizational, Human and Technological

Factors.

The Organizational Factors are related to the actions of the Senior

Management, Administrative Council, Management, Senior Management, and

Advisory/Staff, these functions are in the corporate instance, as an example of

actions of this factor are: the definition of investments, corporate

procedures, and the decisions that affect the area of operations of the

organization, pressures for profitability, continuity, and discontinuity of the

business

Organizational Factors are constitutive elements for Human and

Technological Factors issues, an adequate analysis of the organization's risks

and emergencies is of vital importance for the prevention of major negative

events, and for the success and continuity of the Organization's operations.

The Human Factors are related to the actions of technicians,

supervisors, and middle management who work in the operation of the company's

activity; as an example of a hierarchical level we can exemplify the case of an

oil rig manager, director of a mining company's site and a supervisor of a

manufacturing line; cases related to fatigue, stress, and pressure for results

are issued to be analyzed in this factor.

The Technological Factors are related to the entire infrastructure for

the company's operation, they are the machines, equipment, software, and

production and support facilities; equipment failures are related to this

factor.

Human Error is the tip of the iceberg, it is what initially appears in

major and fatal negative events, it is important to understand the relevance of

exogenous and endogenous variables in the systemically structured

socio-technical system.

“Focus on the Structured Sociotechnical System and not on Human Error”.

First Principle of Proactive Security.

3.1.2. Dynamics of Proactive Safety

To present a dynamic model for Safety Management,

the following model is proposed, shown in Figure 2, as an adaptation of the

boundaries defined by Rasmussen (1997), separating the activity to be analyzed

into three areas:

- Area of Normality – place where the organization

must be positioned; occurrence of non-conformities without criticality for a

major or fatal negative event;

- Danger Area - occurrence of non-conformities

that are critical for a major or fatal negative event, but which have not yet

led to the accident. Area of action of the company's management systems,

normality must be sought, diagnoses must be developed to seek endogenous and

exogenous variables, which may have led to this dangerous area, and through

planning, minimize the possibility of recurrence of these issues:

- Accident Area - apply the emergency and

mitigation plans, to seek a return to the area of normality, as in the

diagnosis of incidents in accidents, the endogenous and exogenous variables

that may have led to the incident must be sought, and through planning to

minimize the possibility of accidents reoccurring.

The

model presents us with an arrow with increased risk, due to social and economic

pressures, for profitability, achievement of goals, granting financial bonuses,

increased workload, and others, which threaten acceptable limits, for safe and

good performance of activities, leading the organization to incidents and accidents.

Figure 2. Proactive Safety

Dynamics Model. Self-elaboration.

It is important to understand systemically the dynamics

of safety management. “Focus on the Dynamics of Proactive Safety and not on

Human Error”. Second Principle of Proactive Security.

4.

Results

Based on

the research carried out, the following cases were selected, which represent

negative events relevant to the research.

Next, we

will present the accidents of Fukushima, Challenger, and Port of Beirut.

4.1. Nuclear Accident in Fukushima

The

Fukushima nuclear accident was a nuclear disaster that occurred at the

Fukushima Nuclear Power Plant on March 11, 2011, caused by the meltdown of

three of the plant's six nuclear reactors.

A 9.0 MW

earthquake occurred at 2:46 pm on Friday, March 11, 2011, with the epicenter

near Honshu, Japan's largest island.

Figure 3. Nuclear Accident in Fukushima. Source: https://brasil.elpais.com/internacional/2021-03-10/10-anos-de-fukushima-golpe-na-reputacao-de-uma-energia-em-retrocesso.html

According

to Hollnaghel (2013), immediately after the earthquake, all the nuclear

reactors in operation at the Fukushima plant, three of the six, were

successfully turned off, but soon after that the external power was lost

because the electrical line was shorted, the electrical panel and the

transformer went out of order, and a power transmission tower was brought down

by the earthquake.

After

the loss of external electricity supply, the emergency standby diesel

generators were successfully started, but approximately fifty minutes after the

earthquake, the tsunami hit the unit, with the wave reaching fourteen to fifteen

meters at the perimeter of the plant, the waves broke the ten meters wall of

the plant. As the emergency backup generators were located underground, they

were flooded with seawater, and electrical equipment, pumps, and fuel tanks

were washed away or damaged, as a result, the plant suffered a total loss of

electrical power.

The

immediate consequence of the loss of electrical energy was the core melting in

Reactors one, two, and three, which in turn caused the massive release of

radioactive materials into the environment, within a few days, of the reactor

buildings of Reactors 1, 3 and 4 exploded because hydrogen that was produced

inside the reactor pressure vessels leaked into the buildings and exploded.

The

plant began releasing significant amounts of radioactive material on March 12,

making it the biggest nuclear disaster since the Chornobyl nuclear accident.

The area became contaminated by the presence of radioactive material released

over it and such exposure caused the site to be continuously irradiated.

The

Fukushima Nuclear Accident Independent Investigation Commission ruled that the

nuclear disaster was "artificial" and that its direct causes were all

predictable. The report also found that the plant was unable to withstand the

earthquake and tsunami. Two employees of Tokyo Electric Power Company died from

injuries caused by the earthquake and another six received radiation exposure

above the acceptable limit for a lifetime.

An

ongoing intensive cleaning program to decontaminate the affected areas and

dismantle the plant will take 30 to 40 years. A barrier in the ground, built in

an attempt to prevent further contamination of groundwater, decreased the

amount of contaminated water collected. In August 2013, however, a huge amount

of radioactive water was detected. There were continuous leaks of contaminated

water at the plant and some at sea. Factory workers are trying to reduce the

leaks through some measures, such as building chemical underground walls, but

they still have not significantly improved the situation.

4.2. The Challenger Case

In 1986,

73 seconds after its launch, the space shuttle Challenger exploded, it was the

first accident of the NASA space shuttle program, and all 7 astronauts died. (Vaughan,

1996; REASON, 1997, 2016).

Figure 4. Explosion of the

Challenger. Source: https://noticias.r7.com/tecnologia-e-ciencia/acidente-com-onibus-espacial-challenger-ha-30-anos-moldou-nova-geracao-de-espaconaves-29062022.

After 6

delays and with the warning that the temperature was below the ideal for

launch, made by mission engineers, and that these low temperatures could cause

an accident, NASA decided to launch Challenger.

The

O-rings of the Space Shuttle rockets expand and contract as the temperature

varies, and on the day of the accident, the temperature at the NASA Space

Center was below freezing, causing the rings to contract, and with this contraction,

there was a leakage of fuel from the rockets, which, upon finding a source of

heat, caused the explosion.

The

issue of O-ring safety dates back to 1977 when engineers at the Marshall Space

Flight Center repeatedly reported to the Solid Rocket Booster (SRB) Project

Manager, George Hardy, that the design of the o-rings provided by Morton

Thiokol was unacceptable. Hardy never forwarded these suits to Thiokol, and the

o-rings were accepted in 1980.

Still,

in the space shuttle design phase, McDonnell Douglas reported that a “burn

through” near the fuel tank would result in a failure that would make it

impossible to abort the mission. The o-rings were then rated Criticality 1,

meaning their failure would result in the spacecraft being destroyed.

Evidence

of serious erosion of the o-rings was verified as early as the second space

shuttle mission, with the spacecraft Columbia, by the Marshall Center. However,

contrary to NASA regulations, the Marshall Center did not report the fact to

NASA's Senior Management, keeping the problem limited to its technical area.

In 1985,

convinced of the catastrophic potential of the problem, Marshall Center and

Thiokol began redesigning the o-rings but did not request a suspension of

flights or the use of o-rings. They treated the problem as an acceptable risk.

Thiokol's

management initially supported their engineers' recommendation to postpone the

Challenger's departure, but in a telephone conversation with a NASA manager,

the latter said: "For God's sake Thiokol, when do you want Challenger to

be launched? in April?" (NPR, 2016). NASA's arguments would apparently be

that if one o-ring failed, there was a second o-ring. However, NASA's own

standards defined that for criticality 1 components, the second element should

be redundancy in case of unpredictable failures, and not as a backup of the

primary element.

4.3.Explosion in the Port of Beirut

On

August 4, 2020, around 6:08 pm, an explosion occurred in the port region in

Beirut, the capital of Lebanon, resulting in more than two hundred deaths and

more than six thousand injured. Hours after the event, the news already

reported that the catastrophe had occurred in Warehouse 12, where 2,750 tons of

pure ammonium nitrate were stored.

Figure 5. Explosion in the

Port of Beirut. Self-elaboration.

In the

explosion at the Port of Beirut, the Lebanese authorities were informed of the

risk of storing the 2.7 tons of Ammonium Nitrate, and the necessary measures

were not taken to transfer this material to a suitable storage location that

could avoid this tragedy. (Human Rights Watch, 2021)

From

2014 to 2020, documents were presented to the authorities of the Port of

Beirut, the Prime Minister, and the President of Lebanon, evidence of the

organizational factor as a precursor to this great tragedy in which more than

200 people died and 6 thousand were injured in an explosion in the port of

Beirut, Lebanon, which completed one year on 08/04/2021.

Storage

of ammonium nitrate, without proper port security for years, is what caused the

explosion.

No

member of the government has yet been penalized for the explosion.

The NGO

Human Rights Watch (2021) accuses the Lebanese authorities of criminal

negligence. In a 126-page report, the entity documented the numerous violations

by politicians and the country's security bodies in the management of this

hazardous materials warehouse.

5.

Discussion

Parameterization and Highlights, Based

on the Proactive Safety Framework, in the Case Studies

5.1 In

the case of Fukushima

The authorities

responsible for the plant were aware of the possibility of larger waves than

those designed to contain flooding of the plant by tsunami waves. A historical

study revealed that a large tsunami occurred in the middle of the 9th century,

estimated at 869 AD and that a researcher had made a strong recommendation to

refurbish the plant in 2006, but the recommendation was reportedly declined on

the grounds that the tsunami was hypothetical and because the claimed evidence

was not accepted by nuclear industry experts.

Recommendations

from the IAEA report (2015) included a few, which specifically address the

issue of overconfidence:

- The

assessment of natural hazards needs to be sufficiently conservative. The

consideration of primarily historical data in establishing the design basis of

nuclear power plants is not sufficient to characterize the risks of extreme

natural hazards. Even when comprehensive data are available, due to relatively

short observation periods, large uncertainties remain in predicting natural

disasters.

- The

safety of nuclear plants needs to be reassessed periodically to consider

advances in knowledge, and necessary corrective actions or compensatory

measures need to be implemented promptly.

-

Operations experience programs need to include experience from national and

international sources. Security improvements identified through operational

experience programs need to be implemented promptly. The use of operational

experience needs to be evaluated periodically and independently.

Regarding the structured sociotechnical approach, the

following stand out:

Economic pressures in relation to the need for

high investments to adjust the height of the walls may have been a prominent

variable for this and other adjustments.

In relation to dynamic security management, the

following stand out:

The recommendation to adjust the height of the

wall was made, but there was a lack of planning and execution of actions to

address this issue.

5..2. In

the case of the Challenger

The

pressure exerted on NASA by society and the government, of 24 launches per

year, was not achieved, as they did not even reach 5 per year. In order to

ensure that its billionaire budget was maintained, and perhaps increased

because despite being reusable, the maintenance of the space shuttle cost

millions of dollars with each launch, which were preponderant issues for the

erroneous decision to authorize the launch of the space shuttle. Space Shuttle.

After

the accident, NASA was prevented from making new missions, while carrying out

safety studies and adaptations. It took 3 years for a new launch to be made,

and only 22 years later, it sent a civilian into space, not by chance, but

another teacher.

Regarding the structured sociotechnical approach, the

following stand out:

The social and economic pressures exerted on NASA

may have been a prominent variable for the effective decision to launch the

rocket.

In relation to dynamic security management, the

following stand out:

The warning was given by the rocket engineers, but

it was not accepted in a decision by the NASA Directorate and the rocket

company.

5..3. In

the case of the Port of Beirut Explosion

In this

case, the Lebanese authorities were unable to recognize the risk and transfer

the ammonium nitrate to a suitable warehouse.

Around

the world, countless numbers including large amounts of the same agricultural

fertilizer that detonated in Beirut began to appear: in Dakar, authorities

found 3,000 tons of ammonium nitrate in warehouses, in Chennai, port officials

admitted they were unsafely storing 800 tons of the chemical, Romanian

authorities discovered nearly 9,000 tons, including 5,000 tons in a single

warehouse. Disaster prevention is not just about preventing distributors from

improperly storing and transporting large amounts of dangerous goods, it is

important to check several issues such as supervision, communication, and

preventive maintenance.

Regarding the structured sociotechnical approach, the

following stand out:

Political and management disorganization may have

been a prominent variable, due to the non-effectiveness of adequate storage of

Ammonium Nitrate.

In relation to dynamic security management, the

following stand out:

The alert was made to the authorities, but the

necessary adjustments were not made.

6.

Conclusions

From the

cases presented of major and fatal negative events, and from the propositions

presented in this article, it is suggested that traditional risk assessments

need to be reassessed. The assessment of exogenous and endogenous pressures on

organizations, the structured socio-technical system, the dynamic management of

safety, and the systemic view of safety, provided us with a way to identify

contributing factors to these major accidents. In this sense, it is a

complement to traditional risk assessments. In risk management, it is important

to use the precautionary principle and conservative measures, and when in

doubt, re-evaluate and use the opinion of experts, to avoid the major accidents

that were described in the cases presented in this article. A decision-making

process that prioritizes the production process, achievement of goals, and

financial issues, and puts Safety in the background, can lead to bigger and

more fatal negative events. These two principles of Proactive Safety, Risks, and

Emergencies are proposed: Focus on the Structured Sociotechnical System and not

on Human Error and Focus on Proactive Security Dynamics and not on Human Error.

Those principles are a complement to traditional risk assessments and can

provide us with bases for analysis, to prevent and minimize these Major and

Fatal Negative Events.

Contributions:” Washington Barbosa: conceptualization,

methodology, writing- original draft preparation, visualization, investigation

Luiz Ricardo: visualization, writing—review and editing Gilson:

conceptualization, writing—review and editing, validation Assed:

conceptualization, supervision, writing—review and editing, validation Mário

Vidal: conceptualization, supervision, writing—review and editing, validation. All

authors have read and agreed to the published version of the manuscript.”.

Funding: This research received no external funding.

Conflicts of Interest: The

authors declare no conflict of interest.

References

[1]

Barbosa, W. R. MODULE 3 - Case

Studies of Major Negative and Fatal Events Internationally and in Brazil.

Proactive Management Blog, 2022. Available at: https://gestaoproativawb.blogspot.com/2022/02/modulo-3-estudos-de-casos.html.

In Portuguese.

[2]

Barbosa,

W. R. Contribuição da Ergonomia para o Desenvolvimento da Segurança Proativa,

Riscos e Emergências dos Resíduos dos Produtos Perigosos da Fiocruz. Congresso

da Abergo 2020. Available at: www.even3.com.br/Anais/abergo2020/294483-CONTRIBUICAO-DA-ERGONOMIA-PARA-O-DESENVOLVIMENTO-DA-SEGURANCA-PROATIVA-RISCOS-E-EMERGENCIAS-DOS-RESIDUOS-DOS-PRO. In Portuguese.

[3]

Dechy N. et al. Learning

lessons from accidents with a human and organizacional factors perspective:

deficiencies and failures of operating experience feedback systems. EUROSAFE

Forum 2011. Available at: https://www.researchgate.net/publication/233997934_Learning_lessons_from_accidents_with_a_human_and_organisational_factors_perspective_deficiencies_and_failures_of_operating_experience_feedback_systems

[4]

Dekker, S.W. The Field Guide to

Understanding Human Error. Ashgate, 2006

[5] Figueiredo, M.G., Alvarez, D., Adams, R.N. O

acidente da plataforma de petróleo P-36 revisitado 15 anos depois: da gestão de

situações incidentais e acidentais aos fatores organizacionais. Caderno de

Saúde Pública 34 (4), 1–12, 2018. DOI: https://doi.org/10.1590/0102-311X00034617

[6]

Filho APG,

Ferreira AMS, Ramos MF, Pinto ARAP. Are we learning

from disasters? Examining investigation reports from National government

bodies. Safety Science, 2021. DOI: https://doi.org/10.1016/j.ssci.2021.105327

[7]

Furuta, K. "Resilience

engineering: A new horizon of systems safety". In: Ahn, J., Carson, C.,

Jensen, M. et al. (eds.), Reflections on the Fukushima Daiichi Nuclear

Accident: Toward Social-Scientific Literacy and Engineering Resilience, Part V,

chapter 24, New York, USA, Springer Open, 2015.

[8]

Greenwood, M. and Woods, H.M.

The incidence of industrial accidents upon individuals with special reference

to multiple accidents. Industrial Fatigue Research Board, AMedical Research

Committee, Report No. 4. Her Britannic Majesty's Stationary Office, London,

1919.

[9]

Heinrich, H. Industrial

Accident Prevention. McGraw-Hill, New York, 1931.

[10]

Hollnagel, E. Barriers and

accident prevention. 1st. ed. Surrey, Ashgate, 2004.

[11]

______. FRAM - the Functional

Resonance Analysis Method: Modeling complex socio-technical systems. Farnham,

Ashgate, 2012.

[12]

______. The FRAM Model

Interpreter FMI: software for FRAM model analysis. Jul. 2019. Available at: https://functionalresonance.com/the-fram-model-interpreter.html

Accessed: Oct. 10, 2021.

[13]

______, E., FUJITA, Y.

"The Fukushima disaster-systemic failures as the lack of resilience",

Nuclear Engineering and Technology, v. 45, n. 1, pp. 13–20, Feb. 2013. DOI: https://doi.org/10.5516/NET.03.2011.078

[14]

______, WOODS, D., LEVESON, N.

Resilience Engineering: Concepts and Precepts. 1st. ed. Burlington, Ashgate,

2006.

[15]

Hopkins, A. Safety, culture and

Risk : The organisational causes of disasters, CCH, Sydney, Australia., 2005.

[16]

______, A. Failure to learn:

the BP Texas City Refinery Disaster. CCH, Sydney, Australia, 2008.

[17]

HUMAN RIGHTS WATCH. “They

Killed Us from the Inside”. 2021. Available at:

https://www.hrw.org/report/2021/08/03/they-killed-us-inside/investigation-august-4-beirut-blast

[18]

IAEA. The Fukushima Daiichi

accident, International Atomic Energy Agency, Vienna, Austria, 2015. Available

at: https://www.iaea.org/publications/10962/the-fukushima-daiichi-accident

[19]

Le Coze, J.C. What Have We

Learned about Learning from Accidents? Post-Disasters Reflections. Safety

Science 51 (1), 441–543, 2013. DOI: https://doi.org/10.1016/j.ssci.2012.07.007

[20]

Leveson N. “A new accident

model for engineering safer systems,” Saf. Sci., vol. 42, no. 4, pp. 237-270,

2004. DOI: https://10.1016/S0925-7535(03)00047-X.

[21]

______. "Safety III: A

Systems Approach to Safety and Resilience", MIT Engineering Systems Lab,

Working paper, Jul. 2020. Available at: http://sunnyday.mit.edu/safety-3.pdf

[22] Llory, Michel. O acidente e a

organização/Michel Llory e René Montmayeul; Tradução de Marlene Machado Zica

Vianna Belo Horizonte: Fabrefactum, 2014. 192p.

[23]

NPR. Challenger Engineer Who

Warned Of Shuttle Disaster Dies. 2016. Available at: https://www.npr.org/sections/thetwo-way/2016/03/21/470870426/challenger-engineer-who-warned-of-shuttle-disaster-dies

[24] Perrow, C., Normal accidents: Living with high-risk technologies. New York: Basic Books, 1984.

[25] ______. Normal

accidents: Living with high-risk technologies. Princeton University Press,

1999.

[26]

Pidgeon, N., O’Leary, M.

Man-Made Disasters: Why Technology and Organizations (Sometimes) Fail. Saf.

Sci. 34 (1–3), 15–30, 2000. DOI:

[27]

Qureshi, Zahid H. A Review of

Accident Modelling Approaches for Complex Critical Sociotechnical Systems, 2008.

[28]

Rasmussen, J., "Risk

management in a dynamic society: A modelling problem", Safety Science, v.

27, n. 2–3, pp. 183–213, 1 Nov. 1997. DOI: https://doi.org/10.1016/S0925-7535(97)00052-0

[29]

______, SVEDUNG, I. Proactive

Risk Management in a Dynamic Society. 1. ed. Karlstad, Swedish Rescue Services

Agency, 2000.

[30]

Reason, J. Managing the Risk of

Organisational Accidents. Ashgate, 1997.

[31]

______, J. Organizational

Accidents Revisited. CRC Press - Taylor & Francis Group, 2016.

[32]

Turner, B. A. Man-Made

Disasters, Wykeman, London, 1978.

[33]

______. Causes of Disaster:

Sloppy Management. British Journal of Management, 5, pp.215-219, 1994. DOI: https://doi.org/10.1111/j.1467-8551.1994.tb00172.x

[34]

______, Pidgeon, N.F. Man-made

Disasters, 2nd Edition. Butterworth- Heinemann, London, UK, 1997.

[35] Vaughan, D. The Challenger Launch Decision: Risky Technology, Culture and Deviance at NASA. University of Chicago Press, Chicago, 1996.

|

|

Copyright © 2022 by the authors. This is an open

access article distributed under the CC BY-NC 4.0 license

(http://creativecommons.org/licenses/by-nc/4.0/). |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Comentários

Postar um comentário