Prevent Tragedies - Lessons learned from the Fukushima accident and RISK MANAGEMENT modules, AND THE PROACTIVE SAFETY METHOD, RISKS AND EMERGENCIES

Figure 1 - Fukushima accident

Lessons learned from the Fukushima accident and ProSREM

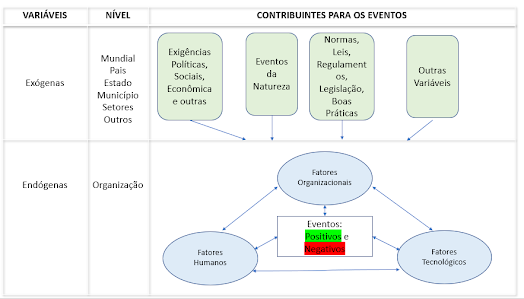

The Fukushima disaster on 11 March 2011 was caused by an external event: an exceptionally large earthquake and a subsequent tsunami. The height of the tsunami, more than 11 m, was a beyond-design basis accident (DBA). This means that although the design of the Fukushima Daiichi plant had considered possible accident scenarios, which involved earthquakes and tsunamis, the safety precautions installed were only designed for a tsunami about half the height of what struck the plant (i.e., the design base was 5.7 m). Because the event was beyond DBA it is easy to understand that the consequences were far more severe than what had been prepared for. All critical buildings that were inundated by water lost their electric power, as did the buildings housing the emergency diesel that was assumed to power cooling pumps in the event of an accident. The plants were all shut down properly at the earthquake, but the residual heat removal stopped when the tsunami arrived. Without residual heat removal, the reactors and the spent fuel storage at the site overheated. In the reactor vessels, the zirconium in the fuel elements reacted with steam to form hydrogen. During the events, at least three hydrogen explosions were registered, which destroyed the leak-tightness of the containments that should have protected against releases of radioactivity. The seawater flooding the site had its own consequences, spreading radioactivity everywhere—onto the ground, into groundwater, and the sea. The inventory of radioactive materials inside the reactor pressure vessels was considerable. A straightforward answer to HOF issues that mattered in this accident can be found in an IAEA report summarizing the results of an international expert meeting in 2013 [37] as follows:

- “The traditional approach to safety

should be complemented by a systemic approach that considers not only the

human, organizational and technological factors that contribute to safety but

also the complexity of the interrelationships among them.

- Regulatory oversight and assessment of

NPP safety should include a safety culture.

- The review of the IAEA safety standards

should consider the lessons from the Fukushima Daiichi accident involving humans

and organizational factors” [37:2–3].

We agree wholeheartedly with these conclusions; however, it may be necessary to go beyond those points, especially to shed more light on the relation of these insights to the event. The critical question, in this case, concerns the design base applied to the plants on the site. According to our understanding, evidence of tsunamis has been found to indicate unable to judge whether or not that was known and acknowledged by governmental or TEPCO officials; nevertheless, it would indicate a core damage probability larger than 10 3 per year (i.e., one magnitude larger than commonly accepted). The events at the Fukushima Daiichi site may also, be considered violations of the single failure criterion (even though this criterion is usually applied for single systems) [39] because a single external event resulted in core damage for four of the reactors on the site.

About this, the IAEA report

[37:14] speaks of the necessity for a paradigm shift, alluding to the need to

understand that the more perfect the system that is developed for a specific

situation, the more inflexible the system becomes for situations that might

occur outside the defined boundaries of that specific situation. One can

interpret this to put more emphasis on risk assessments, both qualitative and

quantitative, by which the need for improvement also applies to the HOF area.

More details, especially for emergency preparedness and responses (such as roles and responsibilities, training, and use of operating experience influencing performance), are to be found in the specific presentations at the expert meeting [37], which include many concrete suggestions for improvements. We have selected the following lessons learned from the Fukushima accident, which give a flavor of issues noted:

- WANO abandoned its former gentleman-like principle not paying attention to technical solutions at the plants of their

member countries.

- The accident was severe enough to cause a

political need for large and visible improvements, which were perhaps a

subsequent goal and reached the EU requirements for stress tests.

- It may be noted that the reactors at the

Fukushima Daini site, located about 20 km south along the coast, did not

experience core damage, the reason being exceptional activities undertaken by

their operational staff to build and operate temporary supplies of electricity.

What becomes evident from this is that the Fukushima accident has led to a change in thinking in the nuclear domain, reinforcing the idea that NPPs are open systems. Although the TMI and the Chernobyl accidents forced the industry to take a broader view of a variety of separate and, in the case of safety culture, overriding HOF, the Fukushima accident showed that one single event, the earthquake, and the tsunami it caused, led to disaster. One can therefore argue that the plant had no protection against the event when it occurred, i.e., the calculated core damage probability was based on the probability of an earthquake causing a tsunami of less than 5.7 m. The reason for this misleading risk assessment goes back to assumptions stemming from the design of a plant, which has its origins in joint interactions between regulation and management. National initiatives, such as the above-mentioned stress tests quickly followed the accident. However, there was also, in the area of HOF, an increased focus on nuclear regulatory processes, risk assessments, and emergency planning, which resulted in, for instance, recommending regulatory bodies to reflect on their own safety culture or further developing safety requirements regarding internal and external hazards [37].

In summary, the scope of HOF has been broadened throughout the period considered here. Although the focus at the outset of the nuclear industry was primarily on the human-machine interface involving ergonomic issues about basic human factors, it expanded over time to include the entire sociotechnical system performance with its inherent interactions in terms of a weak regulator, no emergency plans, and the need to go to the top to get approval for suggestions. Most recently, after Fukushima, this industry again had to learn painfully that NPPs are open systems, and safety-critical influences also overcome the boundaries of a single plant illustrated by a deficient understanding paired with helplessness about external influences on nuclear safety.

Comentários

Postar um comentário