MODULE 2 - THEORY OF THESE TRAGEDY

MODULE 2 - THEORY OF THESE TRAGEDY - SHORT VERSION

This is an abbreviated version, and presents part of the Bronze and Silver Versions of module 2. The Gold Version is accessed in module 4. The links to these versions are found in the texts of the modules, and require authorization to access.

If you are interested in accessing the links to these versions, please send an email to:

washington. fiocruz@gmail.com

INTRODUCTION

We live in a dynamic and complex environment, security management is an important tool to manage this environment. It is recommended that organizations seeking to achieve their goals incorporate safety management throughout their life and activities, including strategies, decisions, operations, processes, functions, projects, products, services and assets.

Safety management can be broken down into two auxiliary functions: risks and emergencies. The first aims to control latent factors and the second, the manifestations of risks in real facts.

Therefore, there are two complementary forms of action: preventive and corrective.

The use of risk management, risk assessment, risk analysis emerged more or less independently in several areas: Nuclear Industry, Insurance, Petroleum Industry, Occupational Safety, Corporate Security, Financial System, Information Security, Security of Products and Processes.

The word risk is used in many areas and with different meanings, such as mathematics, economics, engineering and the field of public health.

MOTIVATION

Despite the efforts developed by companies, organizations, private sectors and the government, a series of major and fatal negative events have happened, such as the cases of the explosion of the space shuttle Challenger, the nuclear accident in Fukushima, the Texas City Refinery and the explosion in the Port of Beirut, which will be dealt with in this work.

Figure - Accidents at Fukushima, Challenger, Texas City Refinery and Port of Beirut explosion

Turner carried out analyzes of serious technical accidents over a long period and came to the conclusion that approximately 20 to 30% of the causes of accidents were technical in nature with 70 to 80% involving social, administrative or managerial factors.

A number of studies on aviation and marine accidents at Qureshi have shown human and organizational factors to be major contributors to accidents and incidents. An analysis of major air and marine accidents in North America during 1996-2006 and concluded that the proportion of causal and contributing factors related to organizational issues exceeds those due to human error. For example, the combined causal and contributory factors of aviation accidents in the US showed: 48% related to organizational factors, 37% to human factors, 12% to equipment and 3% to other causes; and the analysis of marine accidents classified the causal and contributory factors as: 53% due to organizational factors, 24-29% as human error, 10-19% due to equipment failures and 2-4% as other causes.

PROBLEM AND PROPOSAL

Why do major and fatal negative events happen, as presented earlier?

It is verified, according to Llory, even though the causes of these accidents are diverse, they all have an organizational dimension, that is, their root causes must be sought to verify what caused the accident. They also confirm that the non-occurrence of a serious accident and the good performances in everyday life can hide an important issue, as a catastrophe may be about to happen.

Many theorists have presented proposals to prevent or mitigate these events, from initially linear models to more complex models, these major and fatal negative events are complex events, and require a systemic approach, to develop proposals for the prevention and minimization of these negative events, with Ergonomics, the Structured Sociotechnical Approach, Dynamic Model of Safety Management, and the Proactive Safety Method, Risks and Emergencies improve safety management in organizations, being able to prevent and mitigate future major negative events.

EVOLUTION OF METHODS FOR ASSESSING NEGATIVE AND FATAL EVENTS

Traditionally, in the analysis of negative and fatal events, the blame is directed towards the workers, who are the most fragile elements in the companies' chains of command, and there is little analysis of the activities performed by the workers, and their consequences in procedures and adequate working conditions. , supervision and management of activities, investments in the maintenance of facilities, analysis and adequacy of projects, company policies, compensation bonuses for Directors and Management, social and economic requirements, analysis of legislation applied to the activity, among other issues. Security management researchers have focused on this topic in recent decades and have presented their proposals for analyzing the factors that give rise to these negative events.

According to DECHY (2011), we can present the evolution of these periods:

- Technical period until the 1970s: the source of problems is seen as technology; security was mainly based on technical reliability,

- Period of “human error” in the eighties: the source of the problem is seen as the person in particular the operators after the Three Mile Island accident in 1979; allowed improvements in the man-machine interface domains, in the design of operational procedures, in training, among other activities.

- Sociotechnical period in the nineties: After Bhopal (1984), Challenger and Chernobyln(1986) the source of the problem is seen as the interaction between the social and the technical subsystems; Furthermore, the concept of “Safety Culture” emerged after the Chernobyl accident;

- Interorganizational relationship period from the 2000s onwards: the source of the problem is dysfunctional relationships between organizations, in particular with the controlling role of authorities, subcontractors, competitors, other departments within an organization.

We highlight theories and research related to the analysis of accidents, which are correlated with the work presented in this research:

To have access to the continuity of this text, and the bronze, silver and gold versions, complementary to this summarized version, contact:

washington.fiocruz@gmail.com

Part of the text:

Turner (1978) presents the concept of accident incubation, and a six-stage development sequence:

1. Normal state, initially accepted beliefs about the world and dangers. Precautionary norms in laws, codes of practice or traditional customs.

2. Incubation period, accumulation of a set of unnoticed events at odds with accepted beliefs about hazards and norms for controlling them.

3. Precipitating event, disaster begins, general perception changes, surprise and disturbances occur.

4. Events escalate, consequences become apparent and collapse occurs.

5. Rescue and salvage.

6. Complete cultural readjustment. Investigation. Precautionary beliefs and norms are adjusted to fit the newly acquired understanding of the world (“this must never happen again”).

Vaughan (1996) created the expression “normalization of deviations”, and was initially used by this sociologist Diane during the analysis of the causes of the explosion that occurred with the space shuttle Challenger, during its launch on 01/28/1986.

Vaughan noted that the root cause of the Challenger disaster was linked to the decision taken by NASA's Senior Management to launch the space shuttle, despite a dangerous design flaw related to the rockets' o-rings. Diane Vaughan states that this phenomenon occurs when “people in an organization become so desensitized to an irregular practice that it no longer seems wrong”. This “insensitivity” emerges gradually, sometimes over years, as disasters, catastrophes or explosions do not happen immediately, until other deviations and critical factors are “aligned”.

Reason's model (1997), known as "Swiss Cheese" or multiple causes theory, does not defend a single cause as triggering a sequence of events that would lead to the accident, but linear combinations of latent conditions and active failures that constitute several chains. and, after overcoming the safety barriers by aligning their vulnerabilities, they culminate in the accident. In this theory, the influence of the organization on the occurrence of accidents stands out. Thus, investigations must look for latent conditions that can lead to situations conducive to active failures. Thus, the most effective prevention should identify hazards or threats and manage the risks.

Rasmussen (1997) developed ACCIMAP, which focuses on failure analysis at the following six organizational levels: government policy and budget; regulatory bodies and associations; company planning and budgeting; technical and operational management; physical processes and activities; and equipment, it is a proposal with a generic approach and does not use failure taxonomies at different levels of analysis.

Figure - Accimap Model

To have access to the continuity of this text, and the bronze, silver and gold versions, complementary to this summarized version, contact:

washington.fiocruz@gmail.com

Social construction of risk, a basic issue for understanding risk management and preventing major negative and fatal events

It must be accepted that risk is derived from the organization, institutional assumptions and processes; that is, risk is socially constructed.

And to evaluate it, adequate qualitative methods for the social issue are needed.

It must go beyond the analysis of human and technical factors, compliance with legislation and good practices to improve risk management.

Ergonomics and sociotechnics

The evolution of ergonomics shows that its focus has shifted from the workplace to the organizational system.

According to Hendrick (1993), the evolution of the practice of ergonomics can be differentiated into four phases, according to the focused technology. Analyzing each one of them, it is noted that the adaptation of the post is losing strength for the quality of the process, organization and quality of life as a whole.

The 1st phase, called traditional or hardware ergonomics, developed during the 2nd World War, represents the beginning of ergonomics or “human factors” as a formal practical science. Initially, interest was focused on the study of physical and perceptual characteristics (capabilities, limits) of human beings, and the application of data in the design of controls, displays and arrangements of military interest. At the beginning of its application in the civil area, ergonomics was more focused on the physical issues of the work environment and the physiological and biomechanical issues involved in the interaction of human-machine systems. Called physical ergonomics, its application results in increased safety, efficiency and comfort of the system. It is still the biggest field of action for many ergonomists.

From the 1970s, the 2nd phase of ergonomics or environmental ergonomics, which deals with environmental issues (i.e. noise, vibrations, temperature, lighting, aerodispersoids) that interfere with work, has a boost. It was strengthened due to the interest in better understanding the relationship between human beings and their environment, whether natural or built. Ecological issues, very much in vogue recently and so important for restoring the balance of the planet, and with this, the requirements of the Standards (i.e. ISO 14000, 18000), have expanded the role of ergonomists in this line of approach.

With the advent of information technology, starting in the 1980s, the 3rd phase of ergonomics, called cognitive ergonomics, was established. Also known as software ergonomics, it deals mainly with information processing issues. This modality is focused on the interaction interface between man and machine, which is no longer as in the traditional phase (anthropometric, biomechanical and physiological): the operator no longer handles the product, but controls a machine that operates on the product. Information technology becomes an extension of the brain and the interfaces for the operation must take into account cognitive factors to facilitate command.

Macroergonomics, considered the 4th phase of ergonomics, concerns ergonomics focused within a broader context, no longer restricted to specific issues (such as the job or the physical work environment) to also act in the organizational process. The point of view of the first three phases is the operator, or groups of operators, within subsystems of a larger set that is the organization in which they are inserted. The macro vision of current ergonomics focuses on the human being, the work process and the organization, the environment, and the machine as a whole of a broader system. Conceptually, macroergonomics is a sociotechnical approach because it deals with four subsystems: the technological, the personal, the work, and the external environment, which consists of the organizational structure and processes. Its approach is at the same time top-down (because it adopts a strategic approach), bottom-up (because the approach is participatory), and middle-out (because it focuses on the process) (Hendrick and Kleiner, 2000). It differs from the previous ones by prioritizing the participatory process involving resource management, teamwork, working hours and work projects, cooperation, and breaking paradigms, which guarantees ergonomic interventions with better results, reducing the error rate and generating greater acceptance and collaboration on the part of those involved.

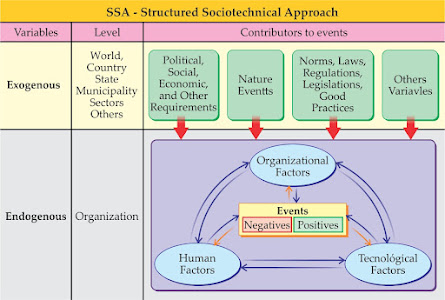

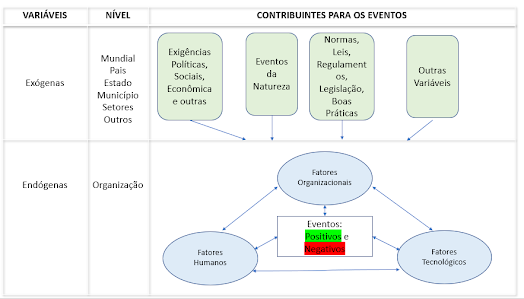

Structured Sociotechnical Approach

The socio-technical approach is divided into organizational, human, and technological factors, which I define as endogenous variables.

As a contribution to this proposal for a sociotechnical approach, I present, based on the case studies research for this work, major and fatal negative events, at the international, national, and local levels (Barbosa, 2022) and the Accimap Model Rasmussen ( 1997), a proposition of the structured sociotechnical approach, where they are included in this analysis are the contributors: social, economic and other requirements; norms and legislation at the World, Country, State, Municipality and Sector levels, which I define as exogenous variables. As a result of the interaction between exogenous and endogenous variables, positive and negative events will occur, which will be shown in Figure.

Figure Structural Sociotechnical

Approach. Self-elaboration.

Exogenous, Endogenous Factors and Lessons Learned

In the case of the Texas City Refinery

The pressures exerted by the need to minimize the loss of profits, led to cuts in investment, operating and maintenance budgets, leading to multiple degradation of safety (degradation of material, instrumentation, numerous incidents) without the appropriate corrective actions were taken.

The Texas City accident teaches us that safety is not a state achieved in a stable and definitive way, but that degradation processes can develop, often without the knowledge of those responsible, or, sometimes, by their deliberation. Most of the safety problems that were at the origin of the accident on March 23, 2005 were recurring problems that had already been identified in the course of audits and investigations. Even after the accident, serious events (fires) continued to occur during the summer of 2005.

CASE STUDIES OF MAJOR NEGATIVE NATIONAL AND FATAL EVENTS

Below we will present the collapse of the Vale dam in Brumadinho, the fire at the National Historical Museum, the accidents on the Santa Teresa Tram and a fatal accident at an Oil Refinery.

BRUMADINHO:

Figure - Failure of Vale's dam in Brumadinho

Failure of the Córrego do Feijão mine dam in Brumadinho, lessons that should have been learned:

• The effectiveness of the drainage system must be improved until the minimum FS established in norms and regulations is obtained;

• Auscultation or monitoring instruments (such as piezometers, water level indicators and inclinometers) must be properly maintained and replaced whenever necessary;

• The Risk Chart, a document that points out the reference levels for the auscultation instruments, must be revised whenever new instruments are installed;

• Surge in surface structures, on slopes and at the foot of dams must be taken into account, as they indicate the failure of the internal drainage system;

• The width of the tailings beach must be respected as determined in the dam operation manual;

• Geotechnical investigations must be deepened so that the parameters that characterize the residues and soils of dikes and foundations are in fact known;

• The emergency communication system, to alert workers and the community downstream of the dams, must be activated immediately after finding a failure;

• Audit companies must be careful when using soil and waste resistance parameters, in view of their great variability; It is

• The top management of companies must be quick in taking decisions after the recommendations made by the audits.

Reference:

Rompimento das barragens de Fundão e da Mina do Córrego do Feijão em Minas Gerais, Brasil: decisões organizacionais não tomadas e lições não aprendidas

Figure - Rescue after the tragedy of the collapse of the Vale dam in Brumadinho

Figure - Brumadinho before and after the collapse of the Vale dam

Continued in Module 3:

CASE STUDIES OF THESE TRAGEDY

https://gestaoproativawb.blogspot.com/2023/08/module-3-case-studies-of-international.html

RISK MANAGEMENT modules, AND THE PROACTIVE SAFETY METHOD, RISKS AND EMERGENCIES.

Comentários

Postar um comentário